The Sirna

Our first timepiece, created entirely in house in our workshop

Sirna

The Sirna is the first timepiece of the new brand STREHLER. A three-hand automatic watch for everyday wear as well as for any formal occasion, made entirely in-house in our workshop in Sirnach.

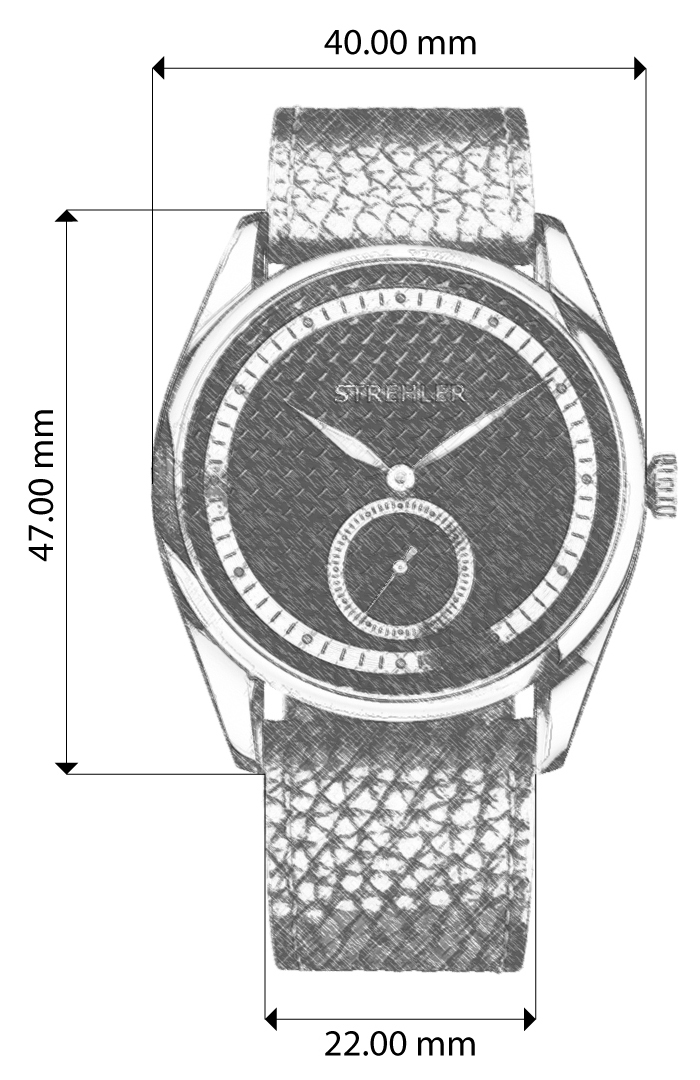

Focusing on the essential, the Sirna has a 40mm stainless steel watch case, made from medical grade steel. And in house of course. With a height of only 8.5mm, it fits perfectly on any wrist. The concave profile that blends elegantly into the lugs makes the watch look more delicate. The Sirna case thus pays homage to Andreas Strehler’s complex Cocon watch case. However, with its harmonious proportions, the polished steel case is quintessentially “STREHLER” and an elegant design in its own right: The fluid lines and the elongated lugs add a distinctly modern touch and beautifully extend the case band. These lugs, gently bending downwards, enhance ergonomics on small wrists and look equally good on more solid ones. With its concave profile, the Sirna offers superb comfort on the wrist, making it a great daily wearer. The classic case – case back – bezel construction is water-resistant to 3 atm.

STREHLER focuses on the essentials, maintaining an uncompromising manufacturing ethos. With its creator’s philosophy, our watchmaking expertise and the exquisite craftsmanship applied, the Sirna is designed to stand the test of time – a watch for many generations to come.

The entire watch, from the movement to the case, dial and hands, is produced by a dedicated team in the brand’s own workshop. Based in Sirnach, a small town of the canton of Thurgau in between lake Constance and the alps, it is one of the very few full-fledged watches manufactured in the German-speaking part of Switzerland.

The STREHLER SA-30 automatic movement

The STREHLER SA-30 movement is a reliable automatic movement, designed by Andreas Strehler and manufactured in our workshop, which was tested on the wrist for many years.

The aim of the development was to create a robust and easy to maintain movement. A thin, but not ultra-thin (and thus oversensitive) automatic movement. Consequently, there are no paper-thin wheels or generic components, every part is specifically made for this movement. The architecture of the movement follows the credo of STREHLER that there are no shortcuts, as is evidenced by the inward angles. With a height of only 4.3 mm and a diameter of 30 mm (13 ¼ ”’), the SA-30 has a power reserve of 60 hours at a frequency of 21,600 A/h (3 Hz). The escapement is a swiss lever special to STREHLER with a free-sprung hairspring and an adjustable-mass balance.

The small second hand is directly driven.

All components of the movement are finely decorated according to Swiss watchmaking tradition using circular Geneva stripes, perlages and bevelled and polished edges.

The open shape of the oscillating weight made from solid 18 K yellow gold allows a panoramic view of the caliber.

Hands and crown

The polished steel hands are also manufactured from scratch and polished in STREHLER’s own workshop.

The crown with the typical butterfly logo refers to watchmaker Andreas Strehler as the originator and designer of the Sirna. This complex floral crown is also made in house and finely engraved by laser.

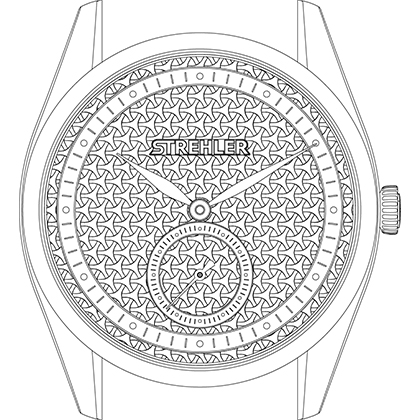

The dial

The dial is the star, machined out of titanium, laser engraved, hand polished and anodized. The three-dimensional pattern and the overall dial have been designed by renowned watch designer and friend of the brand, Eric Giroud. While the three-dimensional pattern shows lively highlights in sunlight, the structure becomes suavely matte with soft indoor lighting. Anodization colours the titanium itself, instead of applying a coat such as PVD, for a much deeper, richer colour. It will never fade. These qualities are difficult to ban on celluloid – or in pixels. The dial must be seen in the wild, or at least tamed on a wrist.

The manufacturing of the dial is a complex operation: First, blank discs are made from titanium sheets, then the holes for the watch hand stems are drilled and the dial feet are positioned. The raw dials discs are then engraved in house in our workshop with our own laser equipment. After the three-dimensional pattern is complete, every dial is hand polished by our engraver – triangle after triangle. Finally, the dial is anodised to achieve its typical deep titanium blue colour.

To complete the dial, the scales for minutes, hours and seconds are transfer-printed on the stainless-steel chapter rings, also produced in our workshop. The chapter ring is then diligently mounted onto the dial, perfectly cantered, avoiding scratches.

Thus, each dial needs several hours of meticulous work to produce its characteristic iridescent effect.

Case

| Material | Medical grade stainless steel |

| Diameter | 40 mm (47mm lug to lug) |

| Height | 8.5mm |

| Crystal | Sapphire with anti reflective coating |

| Back | Transparent sapphire, secured by 4 screws |

| Water resistance | 3 atm |

Dial

| Dial | Titanium, machined, laser engraved, polished by hand and anodised in blue with proprietary pattern circular-brushed stainless steel chapter rings, designed with Eric Giroud |

| Hands | Hand polished stainless steel |

Movement

| Calibrer SA-30 | automatic mechanical |

| Diameter | 30mm |

| Height | 4.3mm |

| Number of parts | 194 |

| Jewels | 30 |

| Power reserve | Minimum 60 hours |

| Escapement | STREHLER swiss-lever |

| Balance | Free sprung balance with 4 regulating screws |

| Frequency | 21’600 vph (3Hz) |

| Function | Hours, minute, small seconds |

| Rotor | 18K gold – steel ball bearing |

| Decoration | Circular Geneva stripes, perlage, bevelled and polished edges with inward angles |